Introduction

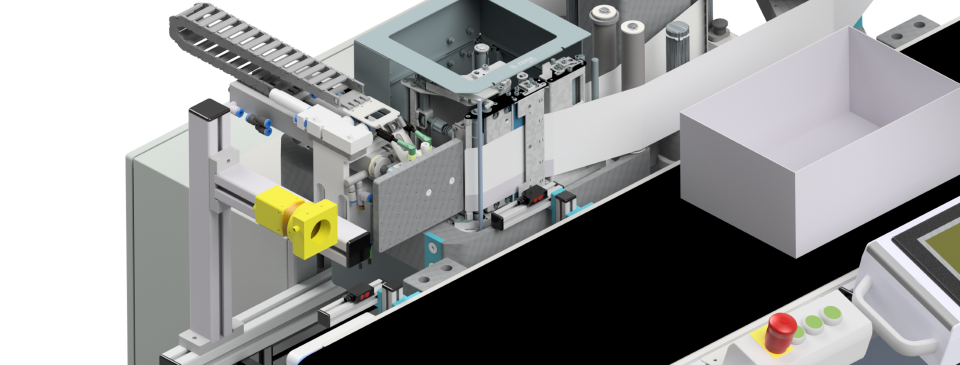

An optical, automatic quality assurance solution offers numerous advantages. High-precision image processing technology ensures reliable quality control in printing and packaging through inspection and documentation of product and process quality in real time.

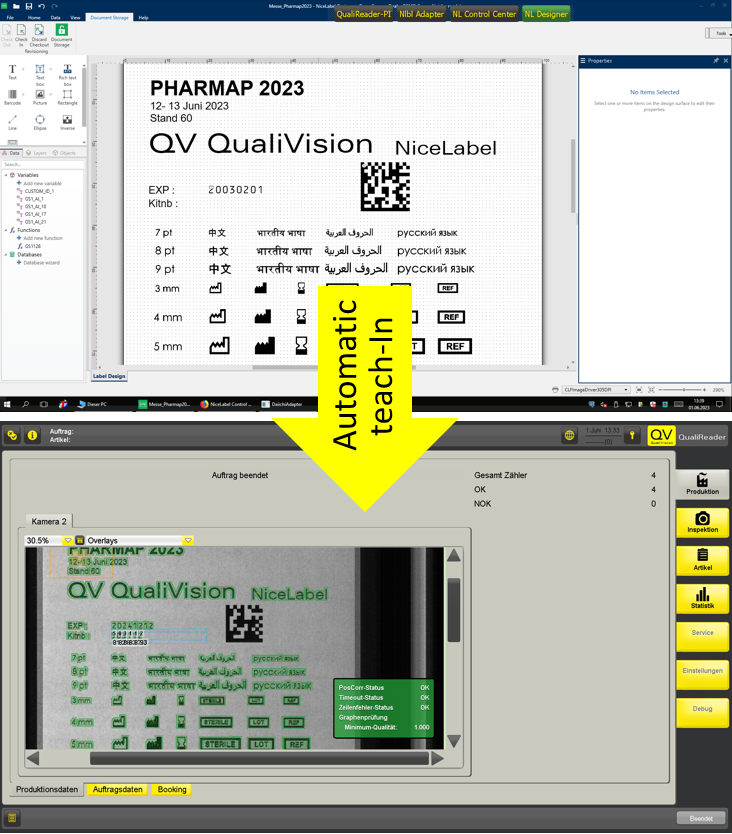

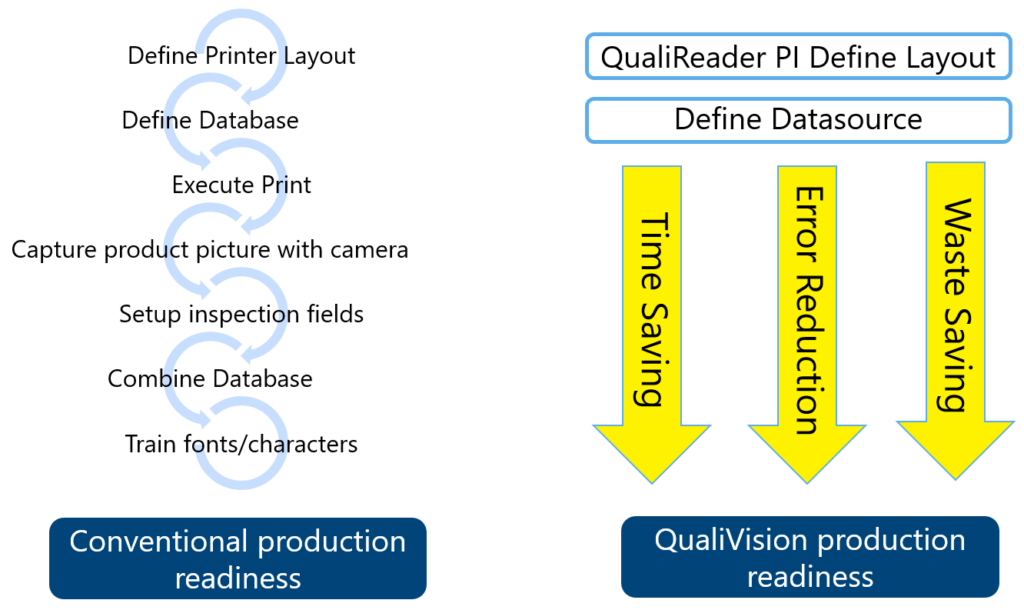

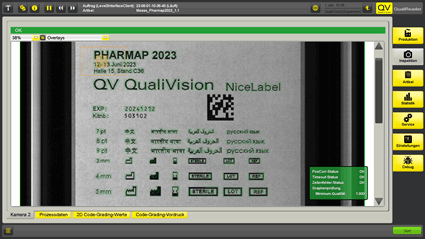

QualiReader PI: Print and Inspect is the efficient solution for printing and direct inspection. The label is created directly in our software or by labelling software, such as NiceLabel, and then used as a digital reference both printing and inspection automatically. This means that only one label needs to be created, which helps to minimise errors.

Quality Control in Printing and Packaging for Images and Code Reading

Both print image inspection and code reading take place.

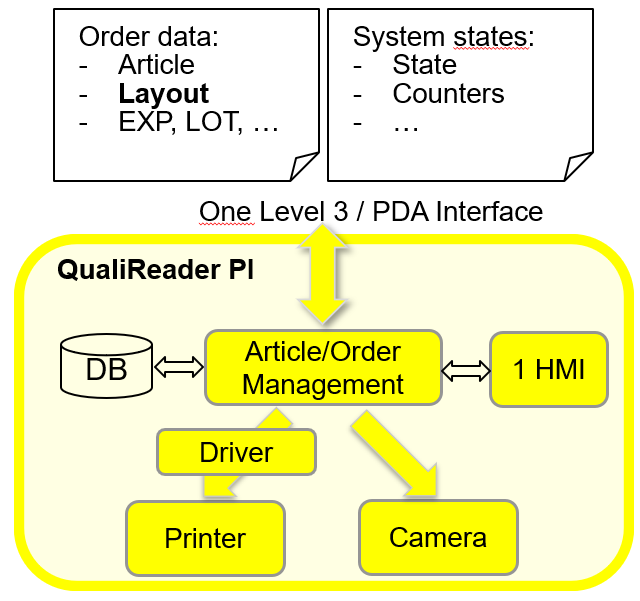

Thanks to internal article management, product changes can be carried out quickly without the need to recalibrate or adjust parameters. Order data can be easily transferred to a large number of Level 3 providers via the open XML interface or scanned in using a handheld scanner. Production data can be returned directly to the Level 3 system or saved manually using reports and order exports.

QualiReader PI saves you time and increases the efficiency of your labelling processes. This technology can be easily integrated into existing systems with a variety of print technologies and media.

Why Choose QualiReader PI For Quality Control in Printing and Packaging

Digital Reference

Teach setup with digital reference results in minimal steps and effortless content configuration. Simplify your workflow and increase efficiency with our intuitive interface that ensures seamless integration and ease of use. Creating new or changing existing articles is very easy.

- Flexible production without golden reference prints

- Enhanced safety and optimized material usage

- User-friendly thanks to automated teach in (e.g. Automated font handling simplifies the process)

- More safety due to integrated version management for articles

- Define the layout once to reduce machine blocking time

Control Printer & Camera Simultaneously

The printer and camera are automatically controlled together and will be set up at the same time. This means fewer interfaces and less hassle. The layout only needs to be designed once.

- Setup of printing and camera parameters

- Serial data handling for fast processes

- One user- and one level 3 interface for different printer and camera setups

- Central user management

- Central audit trail

- Backup and restore for printer and camera setups and articles

Simplify daily quality control in printing and packaging

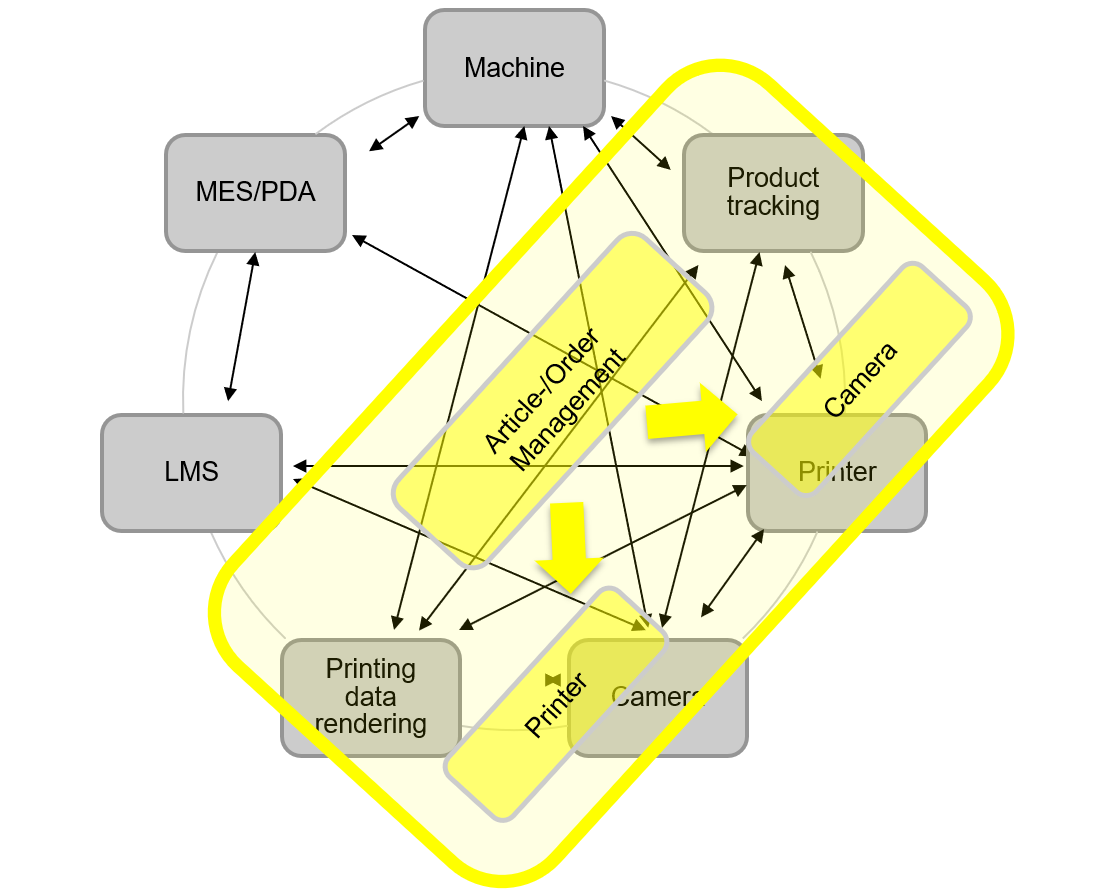

When your goal is verified printing, QualiReader PI is your one-stop shop. QualiReader PI connects your various systems and offers standardized external interfaces, giving your quality control in printing and packaging one standard view. These include the user interface (HMI), the Level3 interface for controlling article and order handling and the production data acquisition for vertical integration connections. Encapsulating the various subsystems offers the following advantages:

- Less training required thanks to a standardized user interface (HMI)

- Optimized interfaces for smoother processes and efficient planning

- Seamless integration

- Streamlined validation process

Full-area quality control in printing and packaging

The area is fully verified, giving you peace of mind. Text (even non-Latin characters), images, and code can be checked. QualiReader PI handles fixed, variable or serialised data. It is also possible to mark areas that should not be scanned.

- Full area checking, letters, symbols, drawings

- Font independent, checks non-Latin characters

Benefits

- Fully automated printing and inspection solution

- Process reliability due to consistency of labelling and inspection data

- Reduce integration complexity

- Serialisation possible

- Collaboration with labelling software possible

- Prepared for many printing technologies and print media

- Universal interface for level 3

- Can be combined with other inspections

- Reduced training and integration cost thanks to same HMI and Level-3 interface for different printing and camera technology

QualiReader PI Application Examples

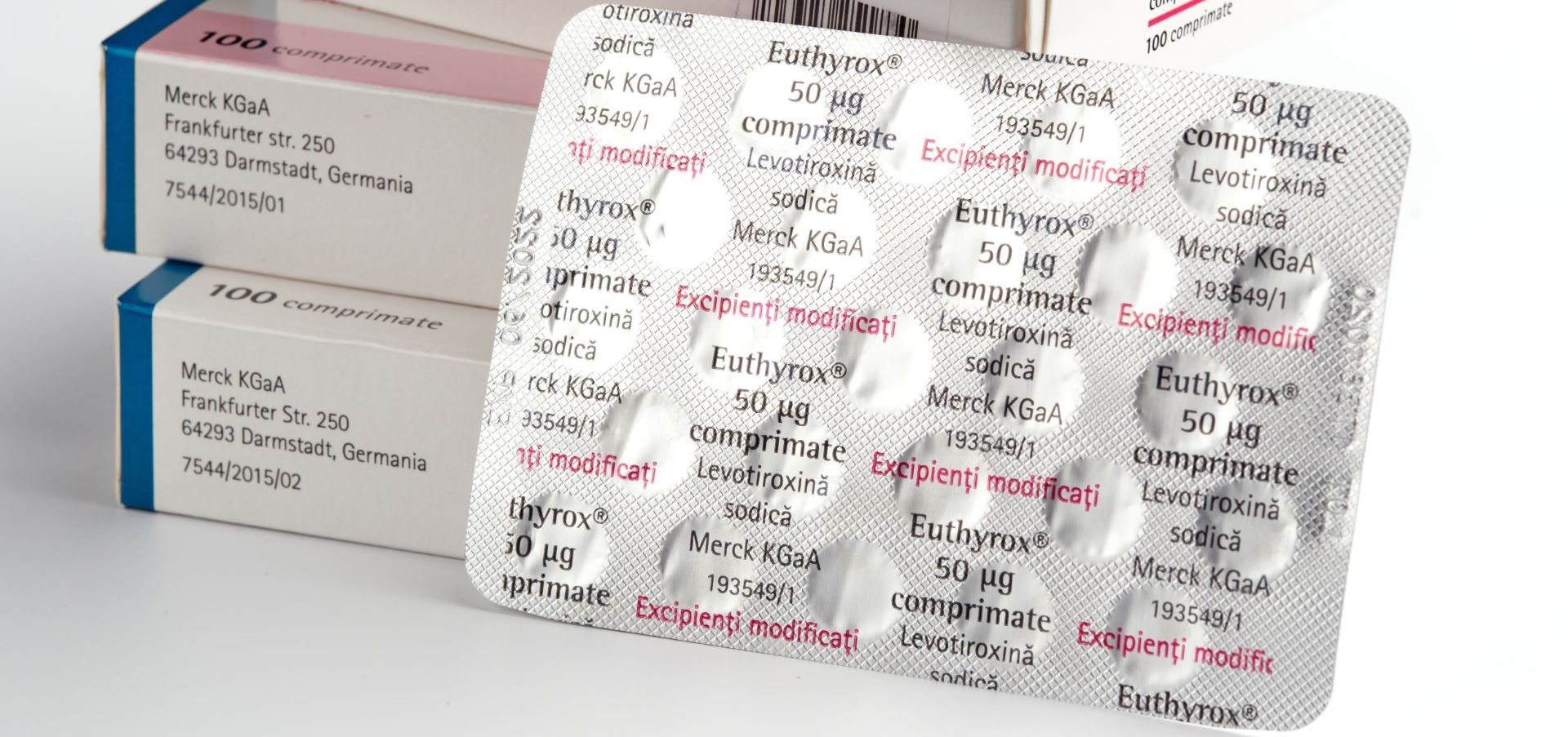

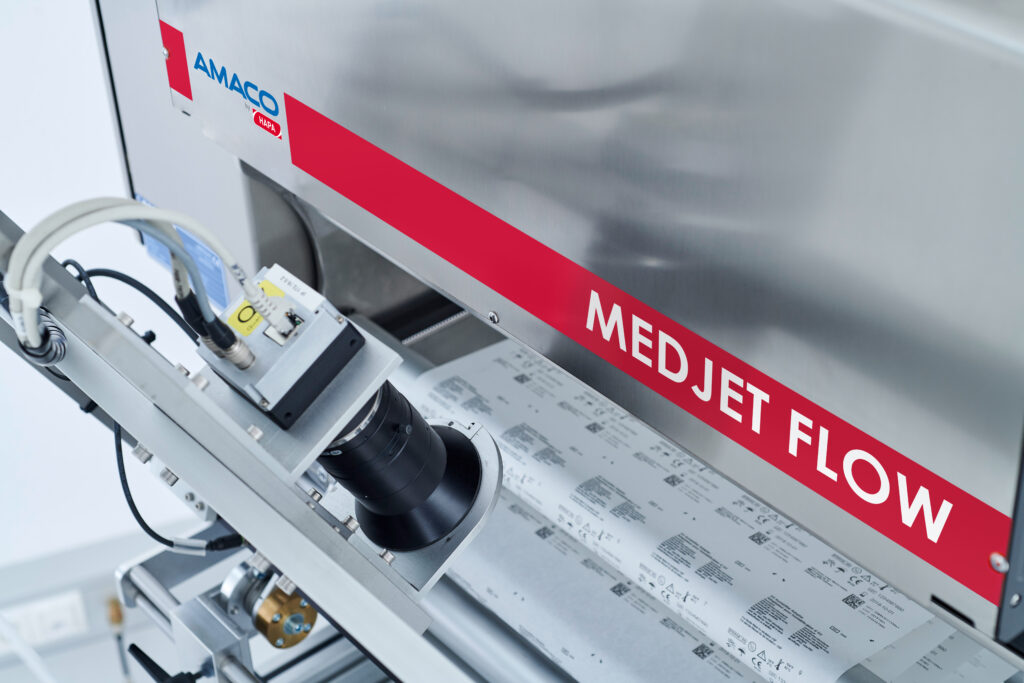

Inline integration kits for printing + inspection

QualiReader PI solutions can be flexibly integrated into printers/labellers or machines thanks to the modular system for end users or OEMs. QualiVision determins the best fitting solution to customer requirements including process integration or level 3 systems. Examples:

- Folding boxes in checkweigher with matrix camera. Rejection is done by the checkweigher unit.

- Medical/Tyvec with linescan camera. Rejection of bad printed foil-index is done by the thermoformer machine

- Plastic foil printing in a flow wrapper, inspection with CIS.

- Label printing with TTO in a labeller, inspection with matrix camera in or after labelling.

Offline (small batch size) printing + inspection

QualiVision offers various “offline” printing and inspection solutions for smaller production batches. These QualiReader-PI systems are based on the QualiVision modular solution and can be adapted to customer requirements in terms of hardware, software and customer process integration. This allows label and direct printing solutions to be implemented in the fields of medical technology, pharmaceuticals, late stage customization and clinical trials.

Examples:

- Roll to roll label printing

- Roll to sheet printing

- Folding boxes serialisation

- Blister direct printing

Supported printing technology

QualiVision is independent of printing technology and suppliers. We support a wide range of different printer brands and printing technology. If a printer isn’t supported, we are happy to develop drivers specifically for you. With QualiReader PI, you get a closed printing and inspection solution that unites different systems into one user-friendly interface. If you have a project please contact us.

Supported printing technology:

- DOD-inkjet

- CIJ

- TT

- TIJ

- Laser

- UV-DOD

Let QualiReader PI streamline and simplify quality control in printing and packaging for you. Contact us today for your consultation.