Printing and Inspection for unfolded boxes

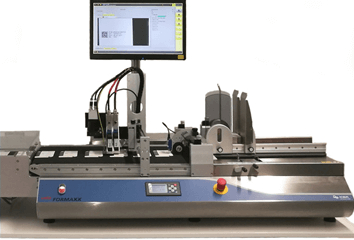

The ideal solution for printing and inspecting flat products, like folding boxes, that are pre-produced or packed by hand.

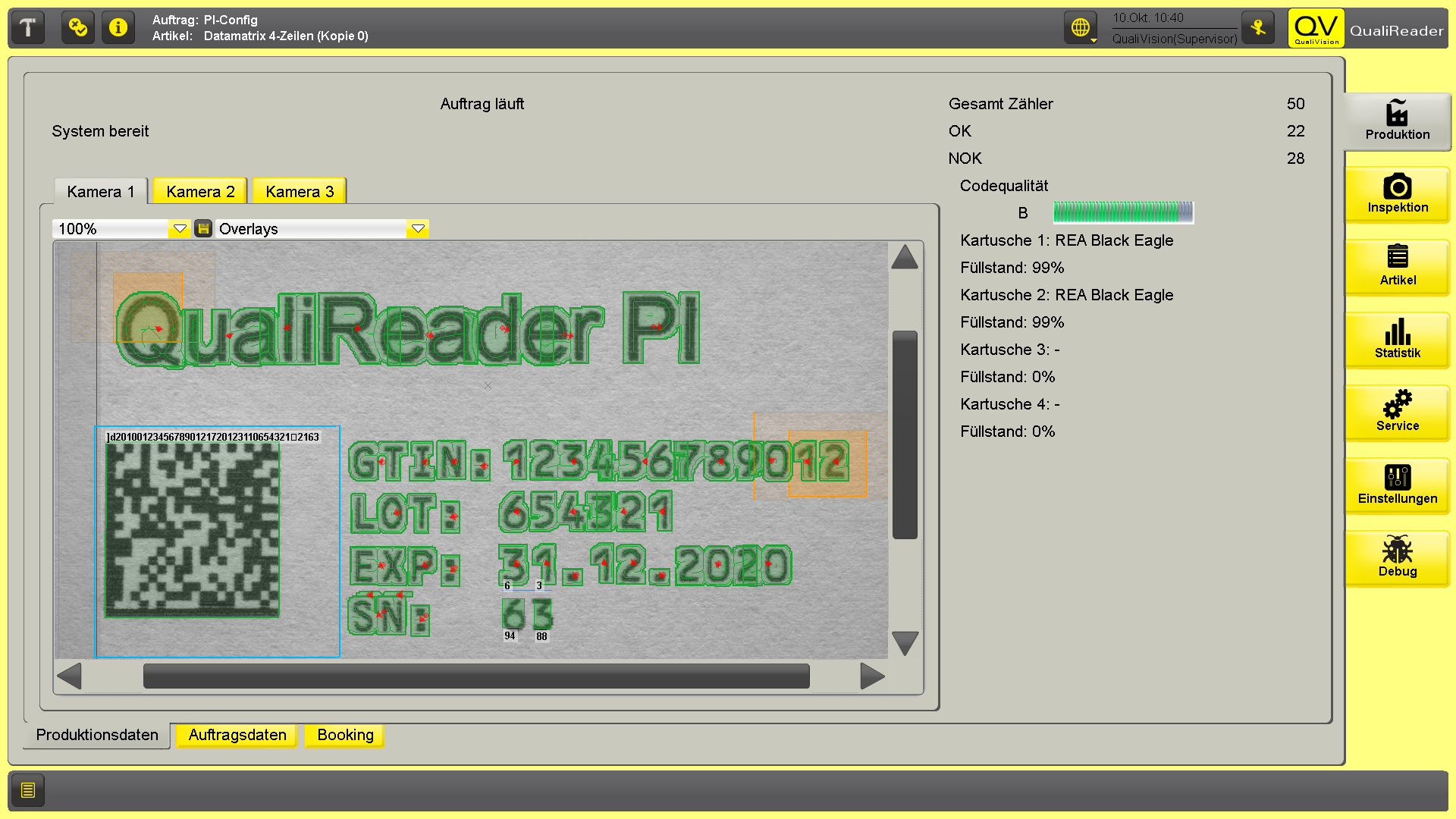

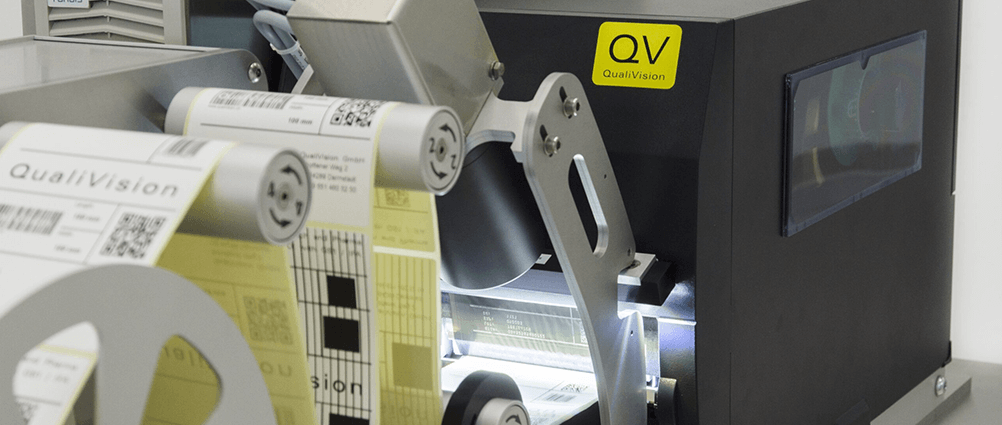

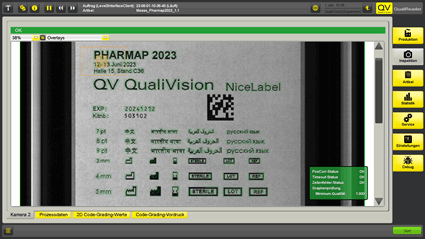

Discover our innovative offline printing and serialization solution with just one central user interface. Our unique software the QualiReader PI controls both the printer and the camera simultaneously, allowing the entire process line to be managed via a single user interface. The system also handles automatic logging and the ejection of bad products via the ejection station.

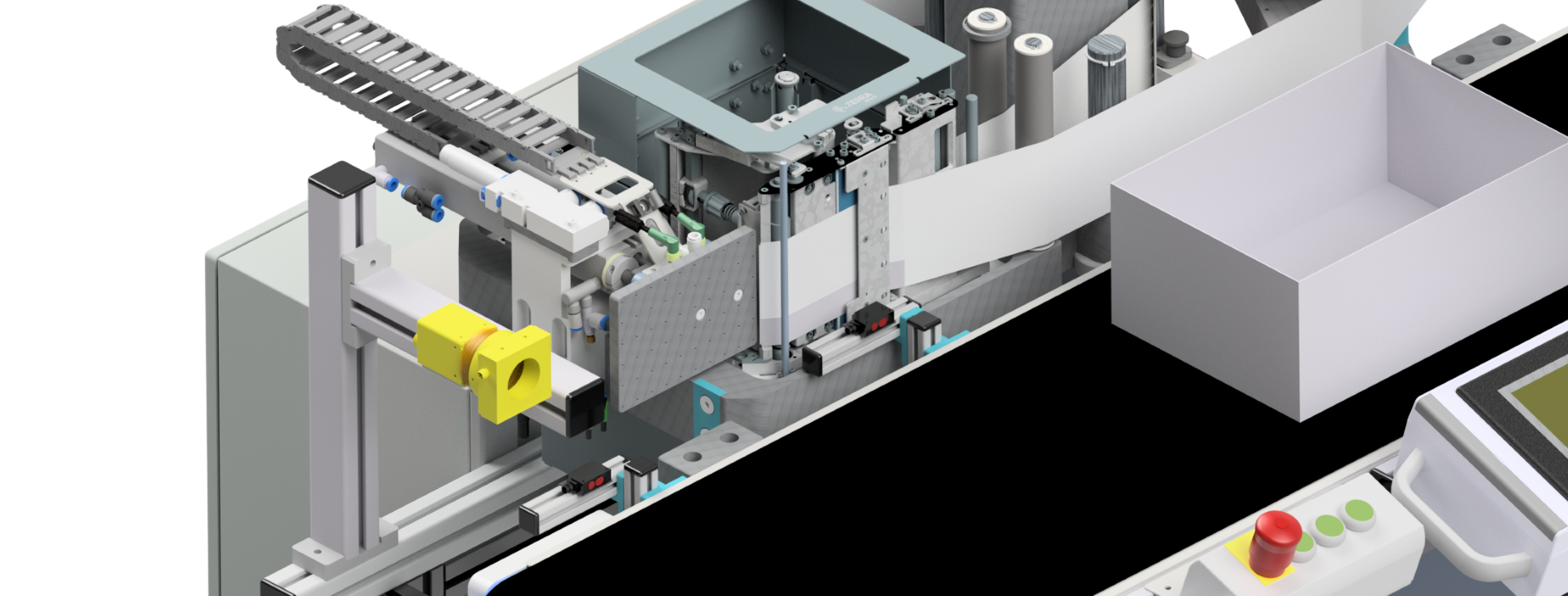

Our solution includes the separator, which separates flat products of all types and guides them at the same distance on the conveyor belt for printing and inspection. After the camera check, the products that are good (OK) are stacked, while faulty (NOK) products are ejected.

The QualiReader PI is the centerpiece of our printing and inspection system, based on the proven technology of QualiVision. This solution not only enables the control of the printing process and the inspection of the products, but also includes integrated software for order and article management. This ensures traceability and fulfils the reporting requirements of the pharmaceutical industry.

Benefits for your company

Fast and reliable

- Flexibility thanks to adjustable format settings

- All-in-one user interface for fast changeing of products.

- Optimization of folding carton production for smaller batch sizes.

Standalone solution

- No integration effort required on site

- Can be used anywhere.

- Integrated on the KBA-udaFormaxx from Koenig and Bauer

Reliable and well-established software

- The QualiReader software runs on the system.

- More than 1000 systems supplied with this software in the field

- User-specific customizations possible.

Spare parts and maintenance

- Maintenance solutions for the proactive care of your equipment, extending its service life and reducing the risk of unexpected breakdowns

- Spare part packages to shorten the reaction time.

For more information or a demonstration of how our QualiReader PI system can help your business, please contact us. We look forward to working with you to make your printing and inspection process safer and more efficient.