Roll To Roll Label Quality Control

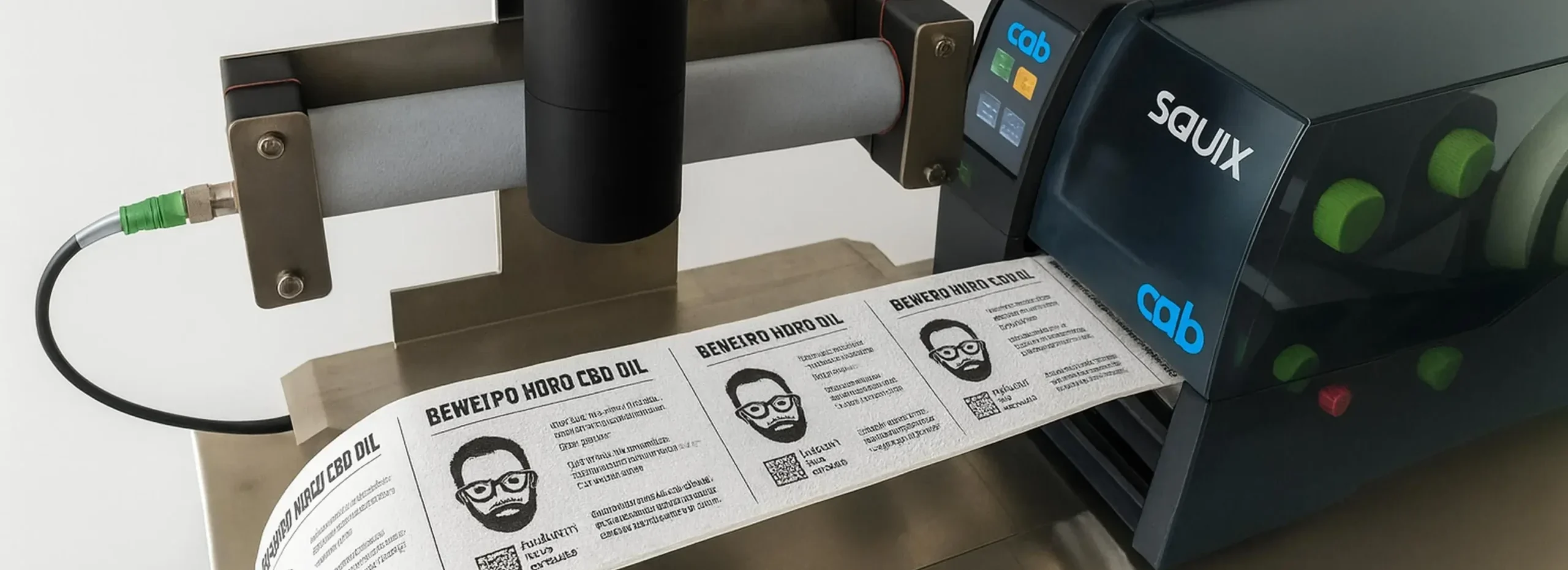

Roll to roll printing is a convenient way to print labels and booklets, but it brings its own set of unique quality control issues. Standard roll printers don’t easily include a QA component. An optical, automatic label quality control solution ensures reliable inspection and documentation of product and process quality in real time.

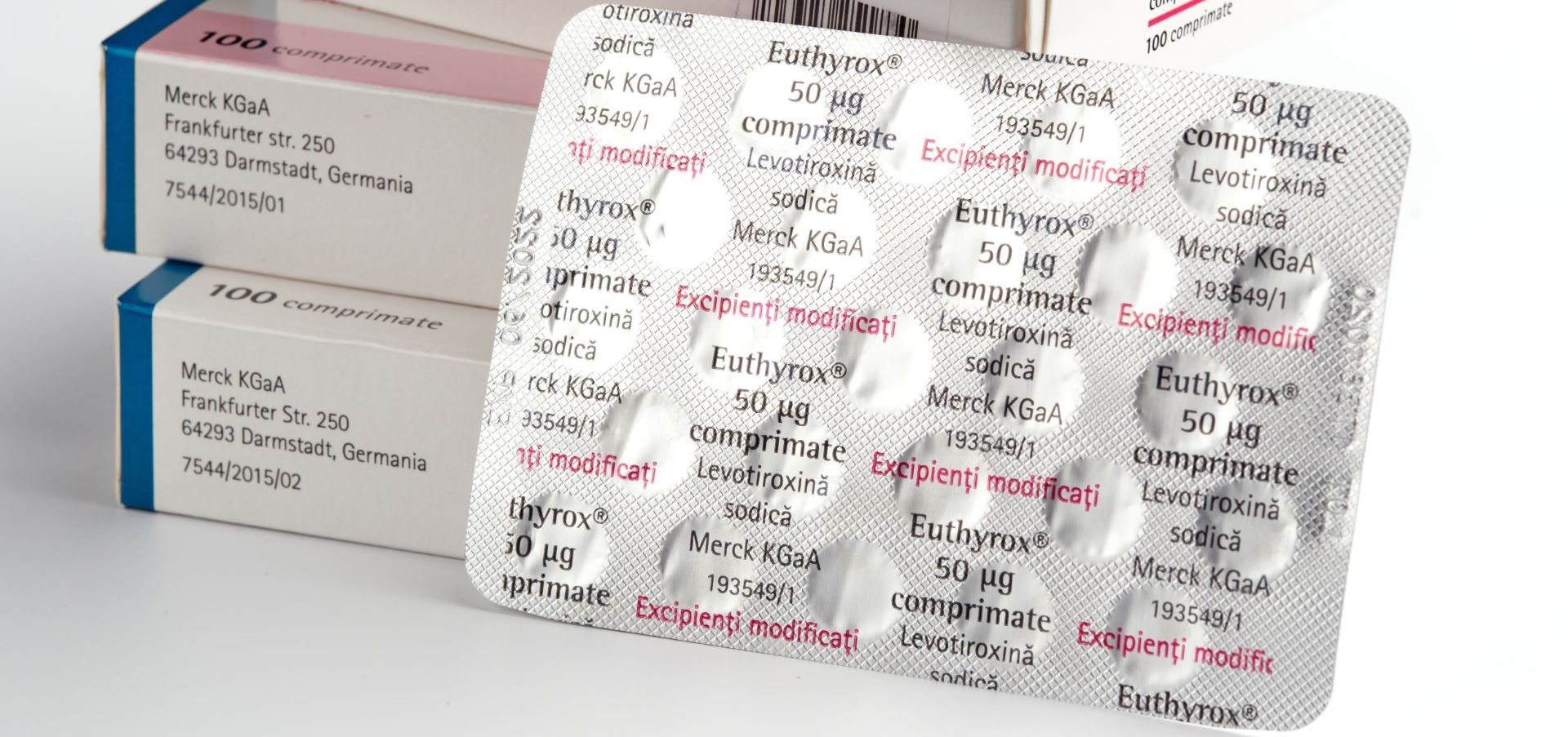

Labels are often pre-printed and then applied to the products manually or using a labelling system. The labels identify and describe the products (content information, track and trace, UDI). Typically, the relevant data is available as a code combined with plain text. Poor printing can lead to misinterpretation of the imprint.

Why is Label Quality Control Important?

There are a few major reasons why label quality control is important. The first is compliance. Certain industries require legibility of plain text. Falling out of compliance could lead to fines and other sanctions from a governing body. Bad labels must be marked, overprinted, or removed.

For all industries, regardless of compliance rules, you want your product to present a cohesive, clear image to consumers. Misprinted labels can lead to consumer doubt and confusion. If errors wind up making stock not fit for sale, retailer relationships may sour as well.

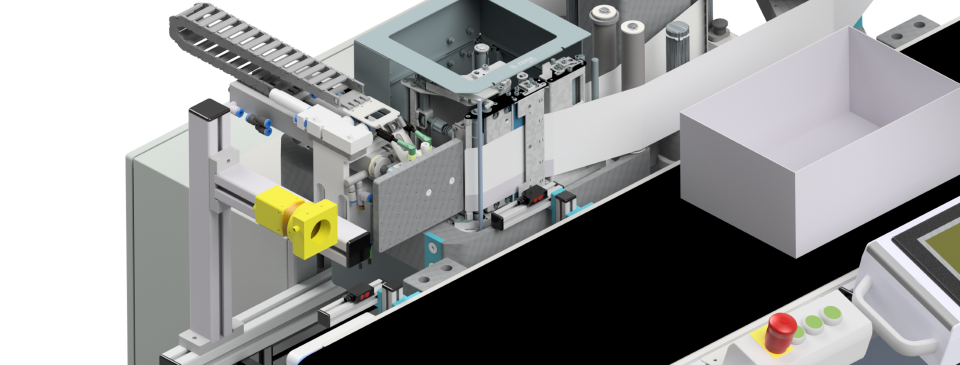

The QualiVision Label Inspector combines the highest standards with the smallest footprint!

System Description

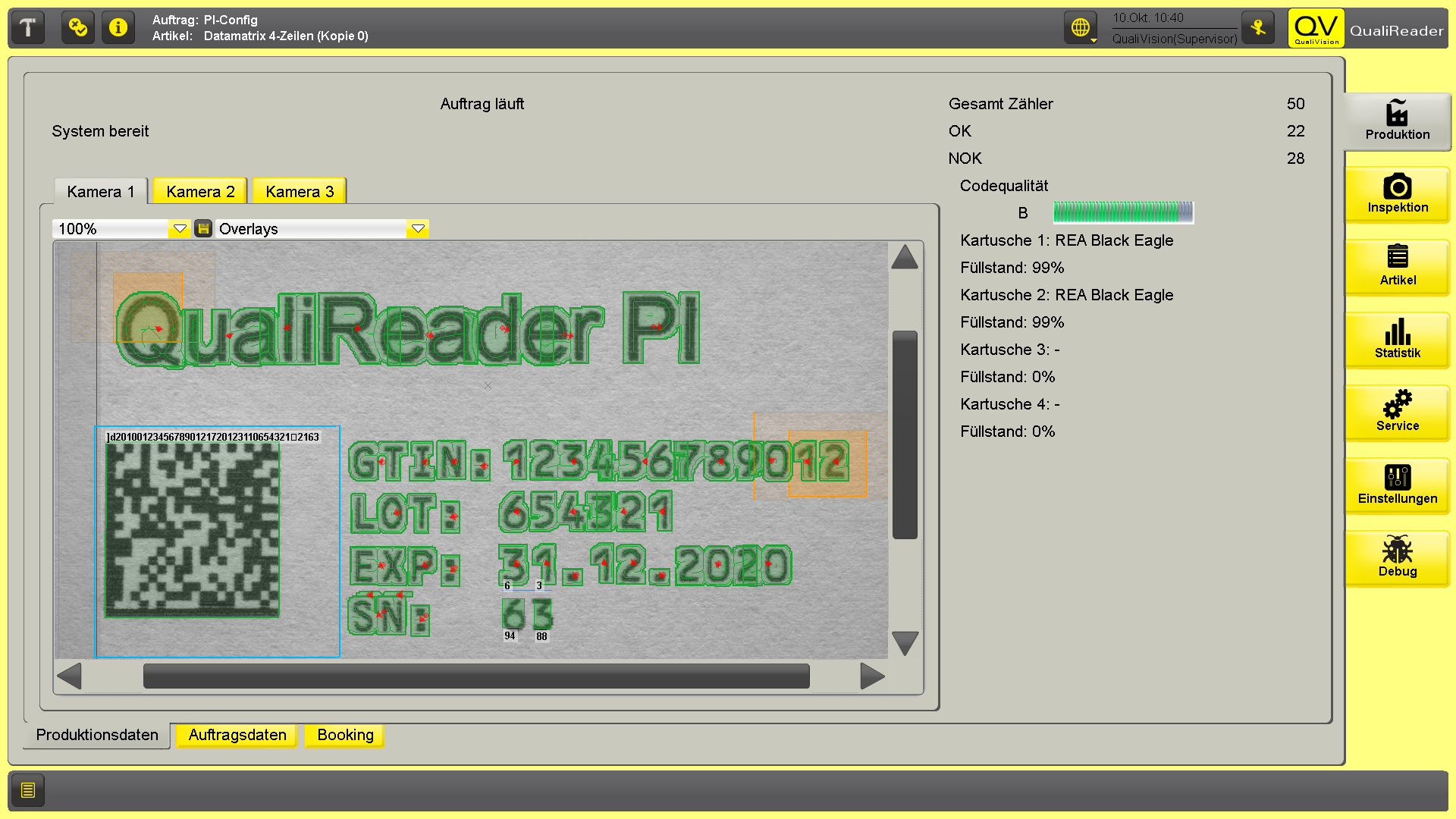

Labels are unrolled, printed and inspected by a high-resolution camera. The camera checks the printed image with decimal point accuracy, reads codes and text and recognizes defects. If an error is detected, the label is automatically retracted, marked/overprinted and documented. A bad label can be removed manually in the standard version and the printing process restarted by acknowledging the action. The printed labels are either wound onto a roll or stacked. The QualiVision printing and inspection system is based on the successful QualiReader software, which allows printing process control, printing and inspection.

Benefits of The QualiVision Label Inspector for Label Quality Control

Fully Customizable

- Printer technology and model depending on your needs

- Modular mechanics (with or without rewinder)

- Software easily customizable to support your processes and fit into your ecosystem

Efficient

- Minimal set-up time thanks to digital reference (teach-in of camera without golden image)

- High productivity thanks to fast job changeover

- Fast training with one user interface for printer and camera

Safe and Reliable

- Based on the proven and thousandfold sold Qualireader PI software

- 100% full surface inspection also of symbols, special characters, non-Latin characters

- Serialisation, balancing/reporting, data logging.

Flexible

- Modular system for small and medium order volumes

- Connection to LMS, MES, ERP

- Integrated order and article management

- Integrated layouting tool

For more information or a demonstration of how the QualiReader Label Inspector can help your business, please contact us. We look forward to working with you to make your label quality control process safer and more efficient.