Installations-Kit for Print-Inspection

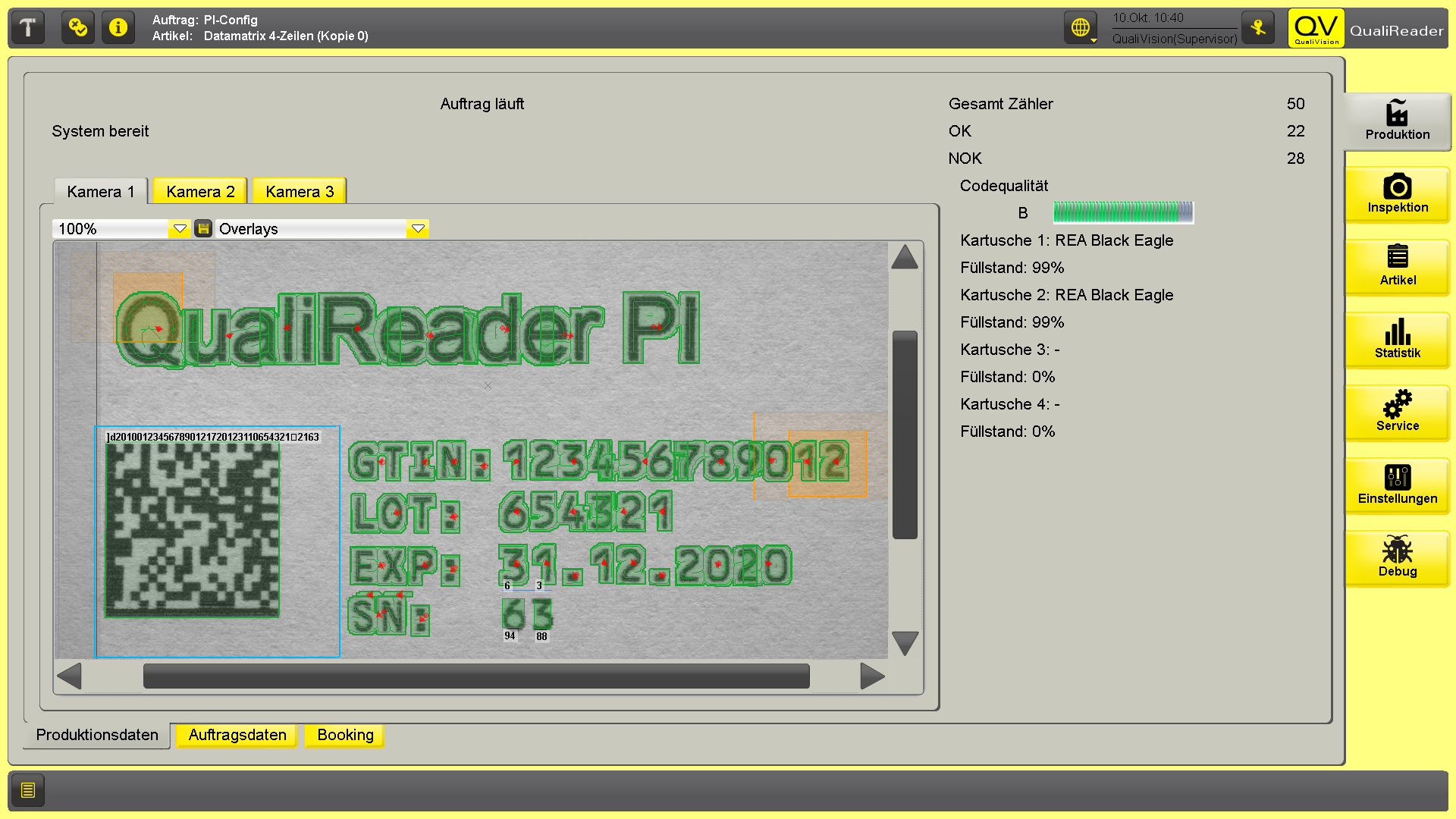

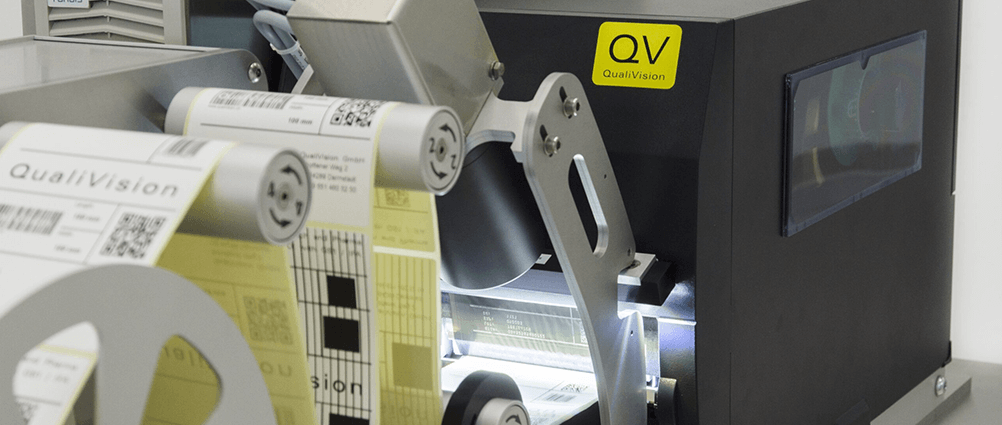

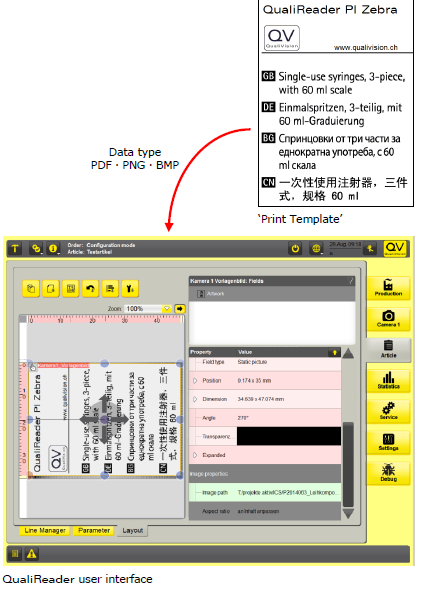

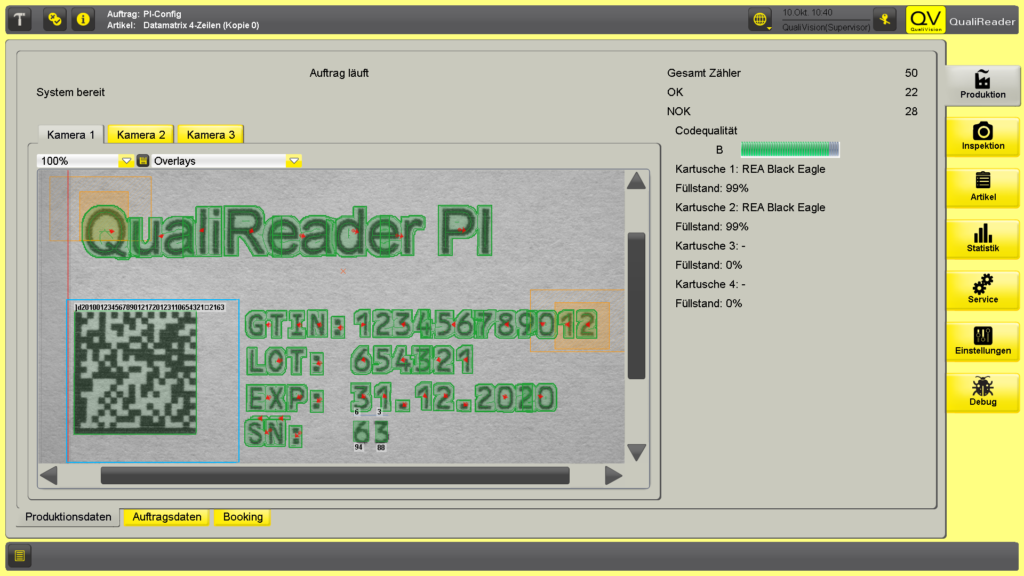

The core of the unique QualiVision solution is the concept that the print layout is automatically used as a digital reference for the camera inspection. Design the label in the integrated label layouter and all your QualiVision inspection systems are ready to go, on all lines in all locations (‘single source of truth’). QualiReader PI checks each printed product and compares it with the digital artwork. This eliminates manual processes and saves time.

Automatic one-step teach-in directly from digital layout

100% inspection of any data (fixed and variable)

All-in-one solution for full-area quality assurance of imprints

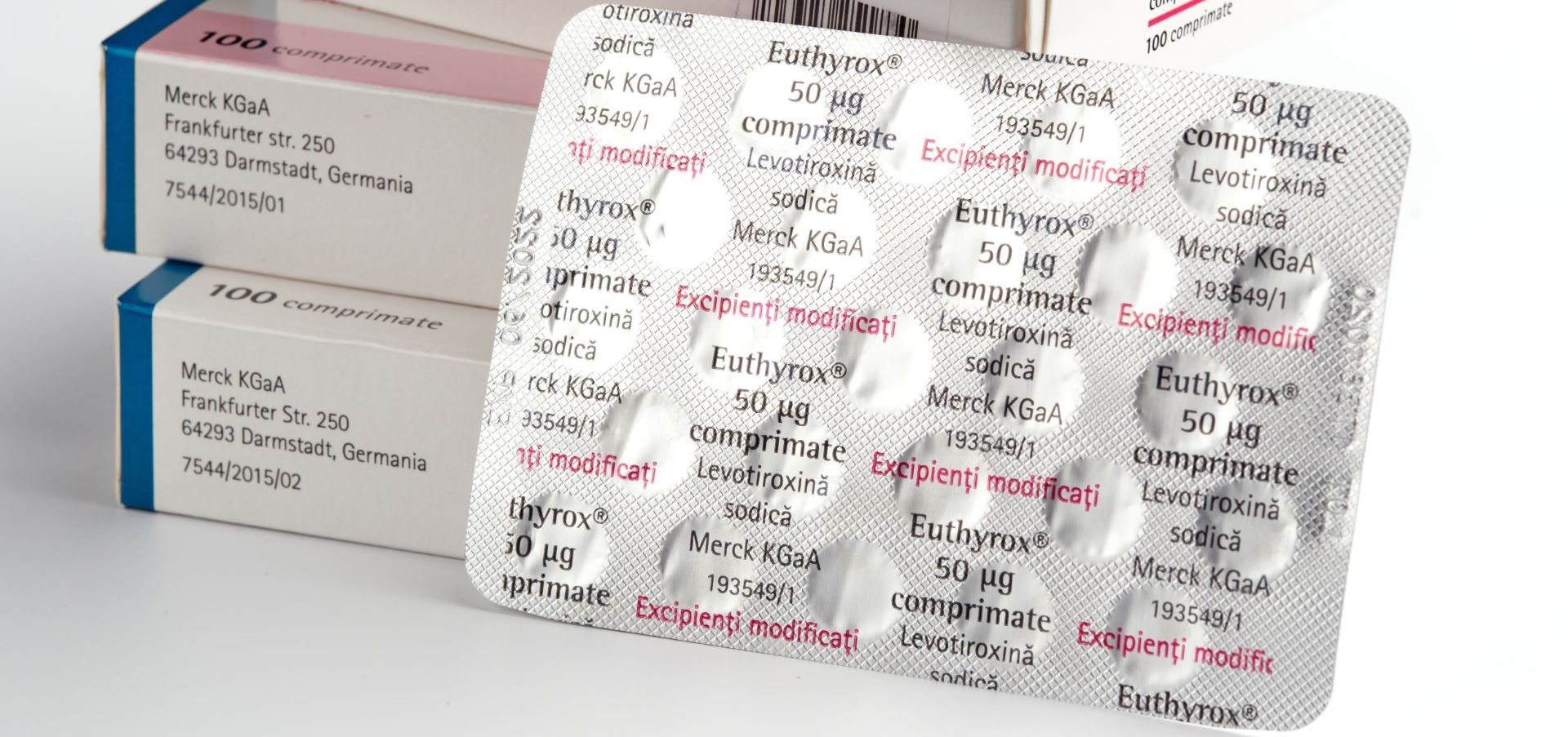

Advanced 2D codes offer significant advantages to all market participants. These codes not only store basic product information such as expiry date, batch and serial number, but also enable a direct link to product-specific, dynamic websites.

For manufacturers, this technology offers a number of advantages: Smaller codes enable more efficient use of available space on product packaging. Improved recall management is made possible by the precise traceability of individual products, which allows quick and targeted measures to be taken in the event of a crisis. In addition, the use of 2D codes contributes to counterfeit protection by making it easy to check the authenticity of products.

In retail, 2D codes make stock management considerably easier. Products that are approaching their best-before date can be automatically reduced in price, which increases sales opportunities and reduces food waste at the same time. This increase in efficiency leads to optimized warehousing.

Consumers also benefit directly from the introduction of 2D codes: they gain access to detailed product information and can check the authenticity of the products themselves. The possibility of traceability creates additional confidence in the safety and quality of the products purchased.

In summary, 2D codes enable a more transparent, safer and more efficient product chain from production to the end consumer, which benefits all market participants.

QualiVision Solution

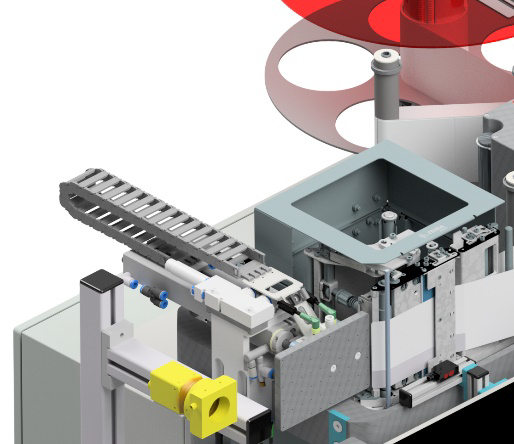

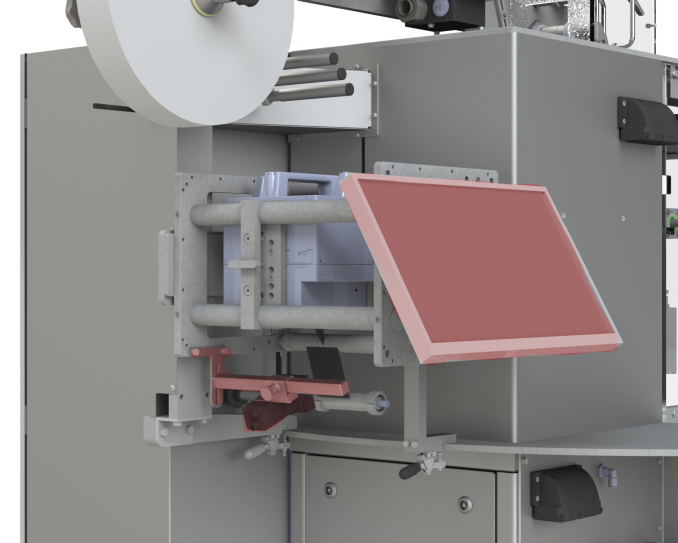

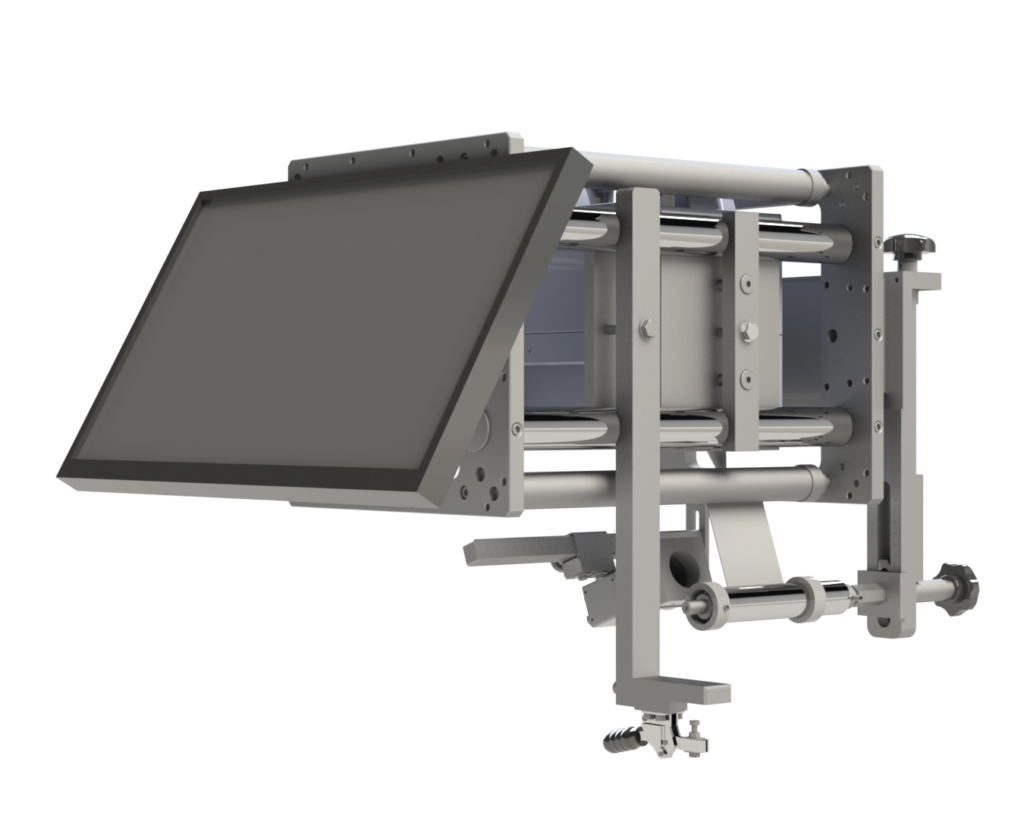

Highly automated processes with flexible inline digital printing require camera inspection and flexible interfaces. The heterogeneous production conditions and installation situations call for a flexible modular solution that can grow with the requirements. With the QualiReader PI, QualiVision offers a modular system that simplifies project planning, service and operation through system integration and standardisation of interfaces.

Fully automatic print and inspection system consisting of:

- Integrated software solution for certified print

- Camera with illumination

- Small control cabinet with controller, UPS, I/O interface

- Touch-HMI

Benefits for your company

Flexible

Flexible machine integration for new machines and retrofit

Proven solution

Proven solution for various printing technologies and cameras

Quick set-up

Minimum set-up time thanks to automated one-step teach-in

Full-surface print inspection

Full-surface print quality control: 1D/2D codes, texts (independent of character sets, e.g. Chinese,

Arabic,…), symbols, graphics,…

For more information or a demonstration of how our system can help your business, please contact us. We look forward to working with you and demonstrating the Integration-Kit for Print-Inspection.