MedTech

In today’s world of medical manufacturing, digital image processing plays a decisive role in quality assurance.

In today’s world of medical manufacturing, digital image processing plays a decisive role in quality assurance, increasing efficiency and innovation in medical devices. Automatic quality monitoring enables processes to be simplified and additional manual work steps to be eliminated. Our customized vision systems offer a wide range of benefits for manufacturers of medical devices. Our solutions enable precise inspection and analysis to ensure the highest standards – from quality control to defect detection. By integrating the latest algorithms and AI technologies, we assist you in the production of safe, efficient and innovative medical products.

Deep Learning

Deep learning technology is revolutionizing the way medical technology is used. It enables the quick and accurate checking of products that are not nicely aligned on a conveyor belt (in a bulk) for defects and completeness, as well as the recognition of mix-ups. Another application is the recognition of pattern, colour or type of product, depending on the product classification. The use of machine learning saves the user an enormous amount of time.

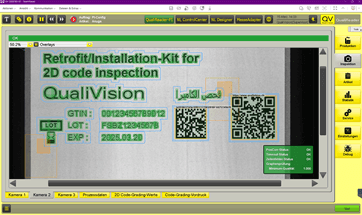

Print and Inspect

Our print control offers a solution for the correct and legible labelling of medical products. Thanks to serialization and aggregation, you have the option of tracking products from production to the end consumer, which increases product safety, customer confidence and counterfeit protection.

Product inspection

Many manufacturers continue to rely on visual inspections by human labor to monitor the quality of their products. This approach can lead to problems such as human error or inadequate quality area specifications and labor retention.

With QualiVision Product Inspection, you can be sure that the quality measures you set for your products are being met and effectively monitored. Using our modular software, QualiReader, we can accurately determine and reliably process measurements such as color, shape, size and more.

High levels of standardization are essential for medical technology in order to ensure valid and comparable results. Camera systems can be specifically configured to monitor and document compliance with certain procedures. This ensures that all processes run consistently, regardless of who is performing them.

Although the initial investment for implementing an optical quality control system with cameras can be considerable, in the long term there are significant efficiency gains and cost savings. A reduction in errors will result in fewer repetitions and corrections, which will in turn speed up production and reduce operating costs.

Should you require any further information, our team of highly skilled engineers will be delighted to assist you in finding the most suitable solution to meet your requirements.