Why Upgrade To A 2D Barcode

By introducing an advanced GS1 2D barcode, you can monitor and control the entire lifecycle of your retail goods more efficiently. These codes enable a direct link to the internet via the GS1 Digital Link Standard, allowing you to provide not only standard information but also customized data about your products.

Significantly expand the possibilities for partner and consumer engagement along the supply chain by making dynamically updatable and personalizable information directly accessible via the product code. Use this technology to increase transparency, improve customer loyalty and optimize your flow of goods.

Advanced 2D codes offer significant advantages to all market participants.

- Store more than basic product information such as expiry date, batch and serial number.

- Enable a direct link to product-specific, dynamic websites.

- Smaller codes enable more efficient use of available space on product packaging.

- Improved recall management is made possible by the precise traceability of individual products, which allows quick and targeted measures to be taken in the event of a crisis.

- Counterfeit protection by making it easy to check the authenticity of products.

Use Cases

Retail

In retail, 2D codes make inventory management considerably easier. Products are approaching their best-before date, especially fresh foods, can be automatically reduced in price, which increases sales opportunities and reduces food waste at the same time. This increase in efficiency leads to optimized warehousing.

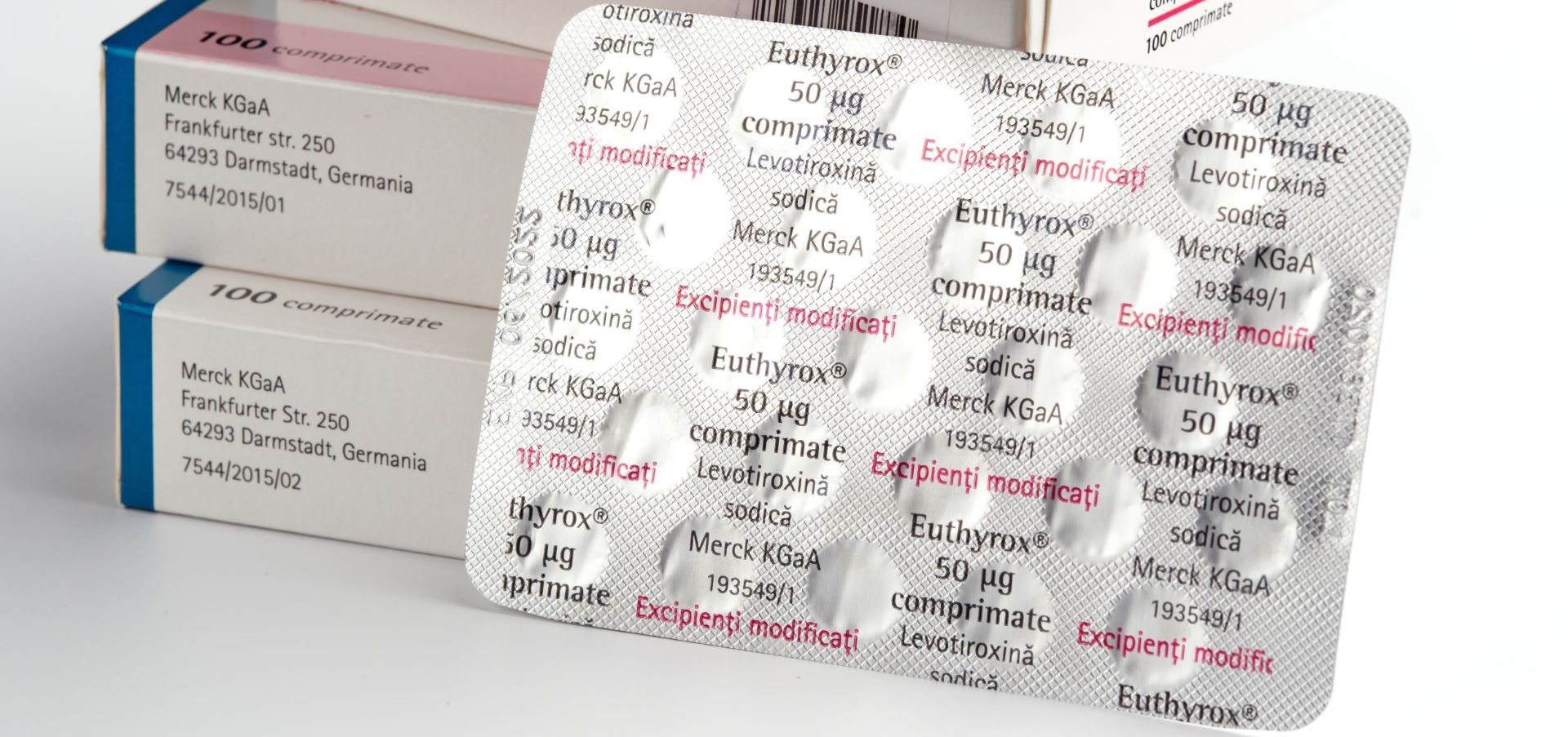

Healthcare

In the healthcare industry, 2 d barcode technology can improve patient safety by delivering accurate product details to consumers’ mobile devices in an easy-to-understand manner. Additionally, healthcare providers can easily track items and get additional information about product use and details with these next generation barcodes.

Consumers

Consumers also benefit directly from the introduction of 2D codes: they gain access to detailed consumer information and can check the authenticity of the products themselves, without a special barcode scanner. In addition to traceability and authenticity, consumers can enjoy interactive marketing experiences through these codes, increasing loyalty and driving repeat purchases.

In summary, 2D codes enable a more transparent, safer and more efficient product chain from production to the end consumer, which benefits all market participants.

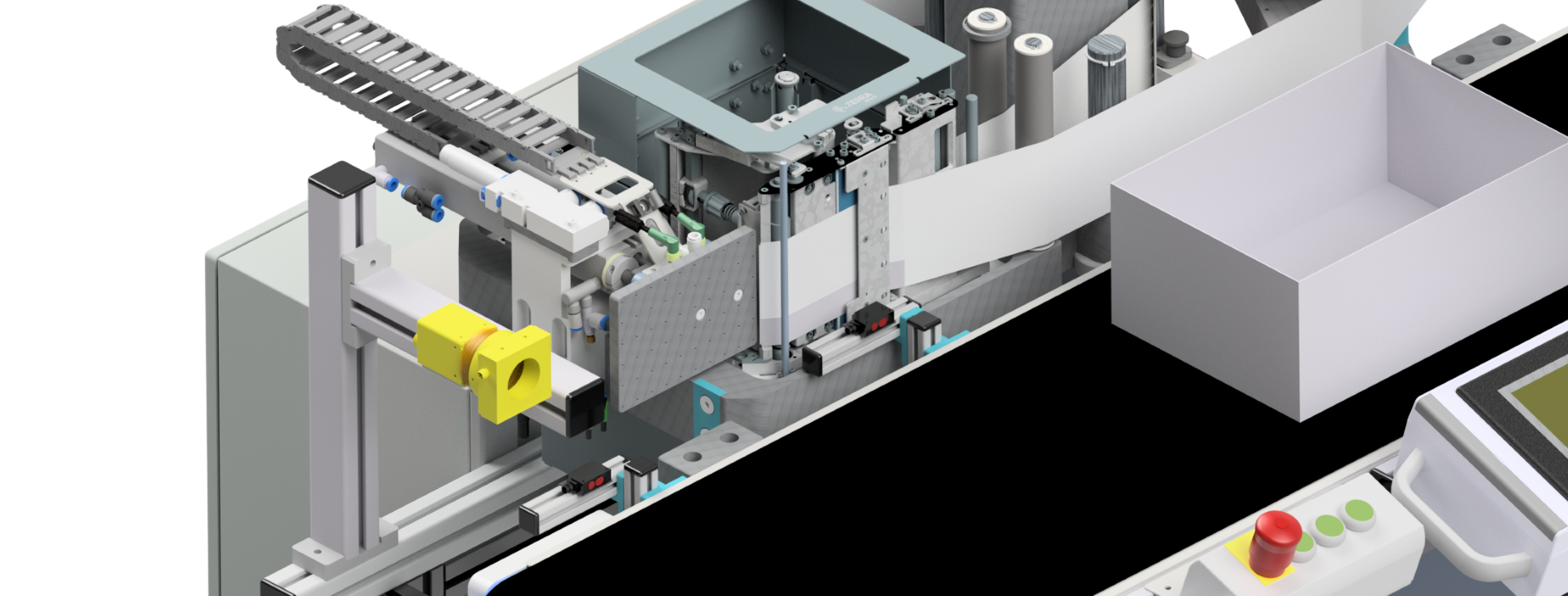

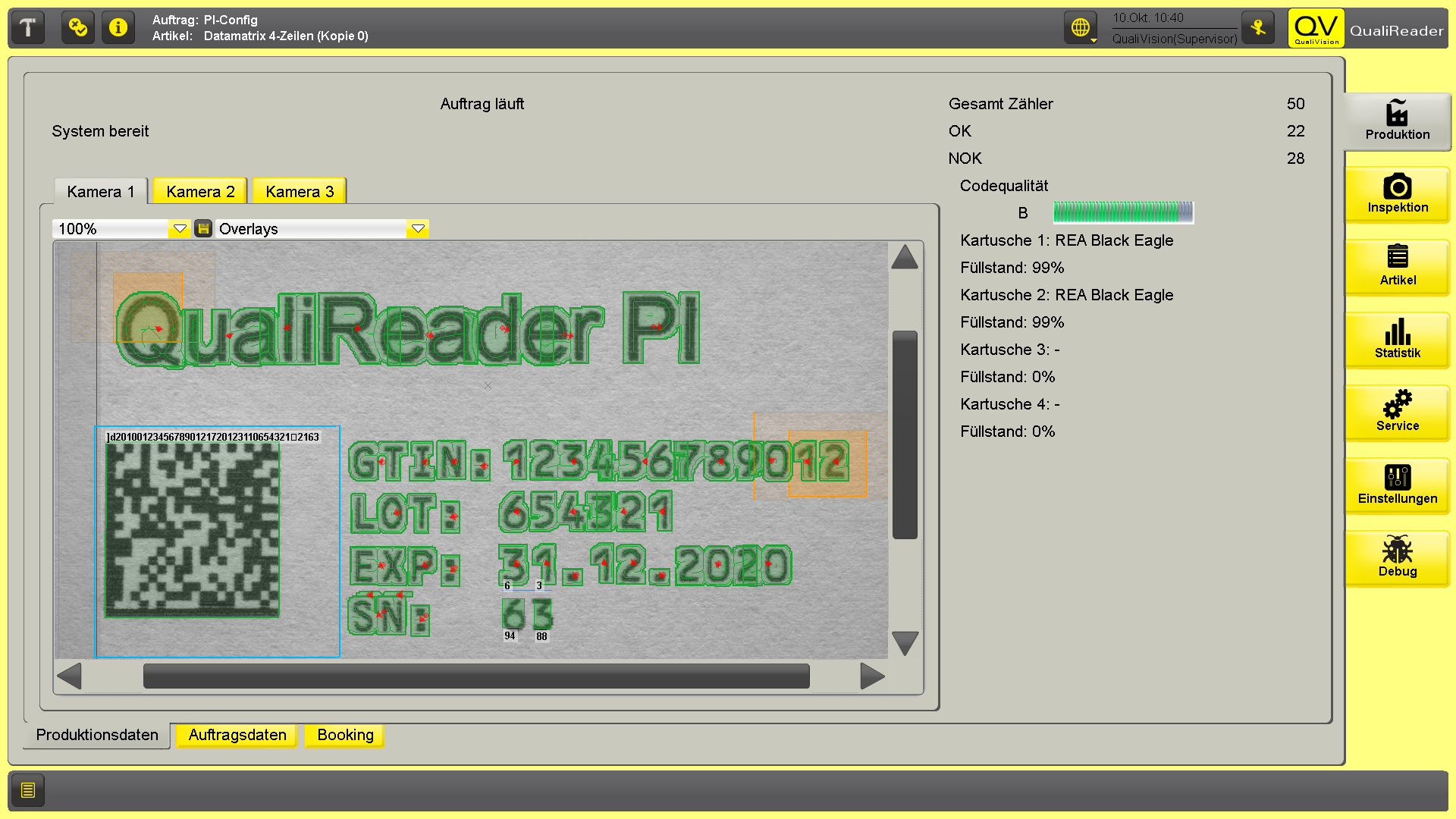

QualiVision 2D Barcode Solution

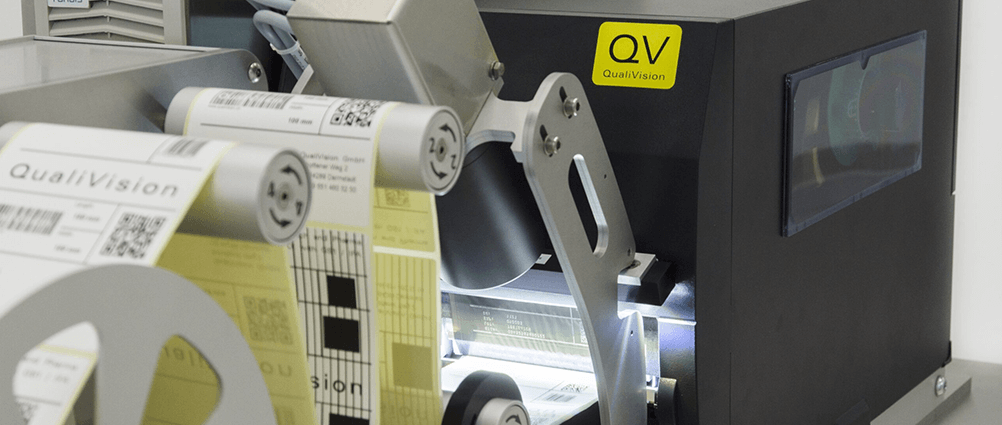

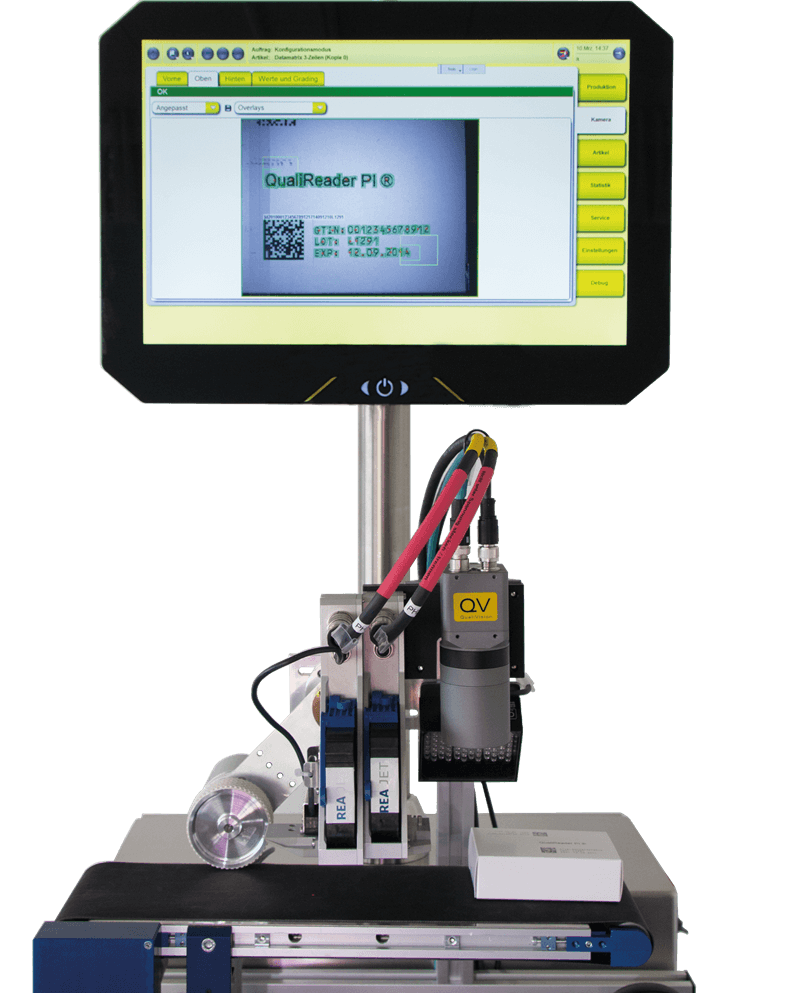

QualiVision offers an installation kit to easily change from one-dimensional to two-dimensional barcodes, including printing and inspection. This kit integrates our innovative QualiReader PI software and a high-quality camera with your printer and rejection unit to smoothly create, print, and proof 2 d barcode labels or inline printed packaging with 2d codes. Both thermal transfer and inkjet printers are supported.

The kit ensures a thorough proof of the entire printed surface, verifying that your codes are printed legibly, and that your other visual elements, like logos, images, and text, are also perfectly legible and aligned.

Investing in our conversion kit for 2D codes gives you the decisive advantage in our modern economy. Increase productivity and demonstrate your innovative spirit to your customers.

Advantages For Your Company

Future-Proof

The kit is ready for various code types, including both QR codes and Digital Matrix codes. It is also prepared for serialization and various printers. New printers are added on an ongoing basis.

Proven Software

The QualiReader software is already running on over 4000 installations, was developed by QualiVision and is compatible with many Level 3 providers.

Flexible

The system can be customized according to your requirements. This includes the size of the products to be tested, connection to MES/ERP and LMS, configuration of the user interface and reporting.

Reliability and Support

Our commitment does not end with system delivery. We offer comprehensive support and continuous updates to ensure the performance and security of your printing and inspection solution.

For more information or a demonstration of how our system can help your business, please contact us. We look forward to working with you and using the space-saving 2D codes.

1D vs 2D Barcode: Pros and Cons

Traditional linear barcodes are a relatively new invention, coming into popularity in the 1970s in mass retail. These rows of variable-width black and white stripes are moved over a fixed laser light, automatically reading the code. These codes, first common in a grocery store, mostly provide product identification.

Benefits:

- Easy to produce

- Cheap to create, print, and read

Disadvantages:

- Short character information limit

- Large footprint

The Rise of The 2D Barcode: QR and Data Matrix Codes

2D barcodes or matrix codes started development in the 70s, as companies were starting to put one-dimensional barcodes into practice. While the simpler 1 D barcode won out in UPC codes, the limits of the format became clear as printers and computers became more sophisticated and powerful.

QR Codes

In the 90s, automotive parts manufacturer Denso Wave developed the QR code, signaling the next generation of barcodes.

With a 2 D bar code leveraging not just one informational axis, but two to store data, QR codes use a matrix to place black dots on a white field. Fiducial markers in 3 of 4 corners let optical readers recognize the limits of the code.

With higher information density, the amount of data available boomed, expanding to over 4000 characters.

DataMatrix Codes

While the public thinks of QR codes, retailers and various industries also leverage Data Matrix codes to carry product and tracking information.

Popular on microchips, medical devices, and other small items, Datamatrix barcodes are framed by a solid left-hand and bottom border and a dotted right-hand and upper border, with geometric patterns of black dots encoding the information within this frame.

Slightly more simple than a QR code, Data Matrix barcodes have a storage capacity of 2,335 alphanumeric characters.