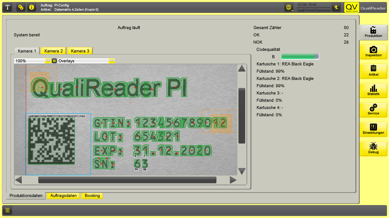

QualiVision on ULMA Blister Machine – Multi-station production line with product + print inspection

Our customer in the medical products industry chose our state-of-the-art vision system to inspect blister packs and achieved remarkable results. Our innovative technology has minimised waste production by eliminating the need to empty the line when changing products. Our system ensures that orders are automatically switched to the next item as soon as the first product of the new order arrives at the relevant inspection station, ensuring a seamless and efficient production line.

With a total of five stations, we provide comprehensive inspection from all angles. These cameras can be controlled and monitored from all 3 screens, allowing flexible and accurate inspection. The functions of our vision system include insertion control, print image control, seal seam control, submix control, label control and printer control. These comprehensive checks ensure that the quality of the blister packs is of the highest standard. Our solution has proven to be essential for reliable and efficient production and we are proud to help our customers achieve their production goals.

The key benefits of our vision system at a glance:

- Efficiency thanks to automatic order changeover: Orders are changed as soon as the first item of the new production is at the appropriate station, increasing efficiency and user-friendliness.

- Comprehensive monitoring: Five stations, each with a camera, allow complete monitoring from all angles.

- Waste reduction