Your Partner for Print Inspection and Automated Quality Control for Over 25 Years

Machine vision has become a powerful tool in quality assurance programs in a variety of industries. From food to medicine, QualiVision’s combination of digital cameras and powerful algorithms has led to an increase in productivity and quality.

Machine vision quality assurance (QA) systems can improve quality in a variety of ways, including:

- Identifying and eliminating broken or misshapen products

- Ensuring correct product placement within a package

- Validating printed codes for legibility and function

- Checking print alignment and color values

- Recognizing packaging tears or errors

- Serialization and track and trace solutions

These are just a few solutions that QualiVision has provided for manufacturers for more than 25 years. QualiVision is your reliable partner for automated quality assurance, machine vision and process optimisation.

We offer custom solutions based on a unique blend of AI and conventional machine vision for all your needs. We accompany our customers through the entire lifecycle from feasibility to production with first class service and support.

Our values – quality, flexibility and reliability – are reflected in every phase of our collaboration. Put your trust in our expertise and let us optimise your production processes together.

A Small Selection of the Over 100 Customers and Partners Who Trust Us

the machine vision experts

QualiVision image processing systems monitor, control and log production processes around the world 24 hours a day. Our solutions combine reliability and flexibility to meet highest customer requirements.

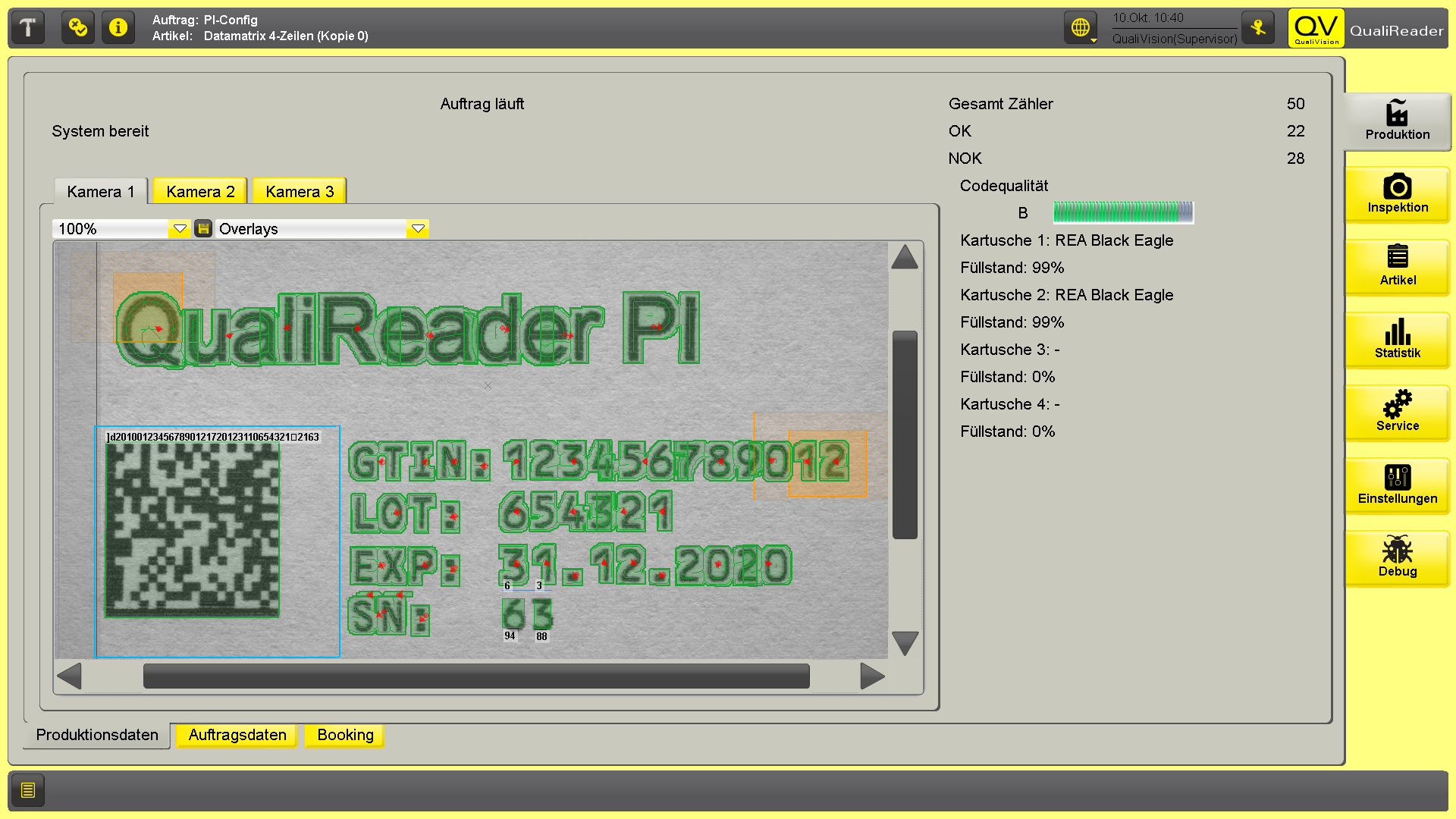

Our modular in-house software QualiReader is compatible with many interfaces and ensures 100% inspection – every surface, every product, without human error, fully repeatable and with audit trail. Our signature software powers applications for product or process inspection as well as print inspection.

We help businesses in every aspect of automatization:

Transitioning from Manual to Automatic Quality Assurance

Manual sampling is prone to human error. We can help improve consistency while lowering your costs with an automated QA solution tailored for your production environment.

Integrating with OEMs

As a solution provider, we enhance the capabilities of packaging OEMs. Our quality assurance solutions showcase the high level of performance of your equipment. We proactively help with the last mile of data transfer, ensuring that production data flows seamlessly from your equipment through our QA analysis to the client’s enterprise software.

Optimizing Existing Production & QA Processes

When manufacturers include QA in their products, they may not integrate with each other or your firm’s management software.

We specialize in eliminating these friction points in your production line, integrating your current equipment and offering a single user interface to manage all your quality assurance touchpoints. Because we develop our software in-house, we can make integrations for you on spec.

Our Machine Vision Quality Assurance Solutions

QualiReader – Unique SW Platform

Modular software framework serving as platform for all our solutions

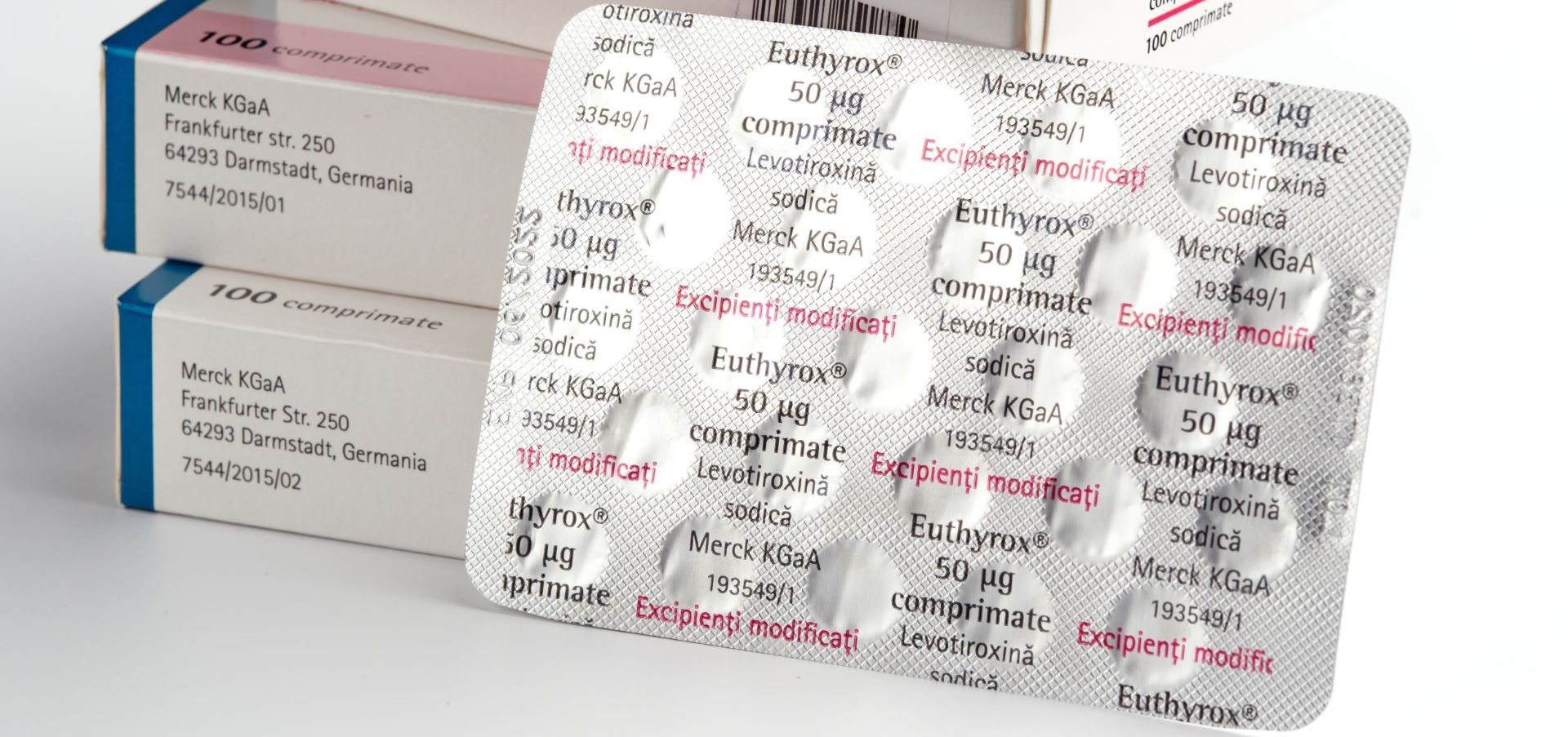

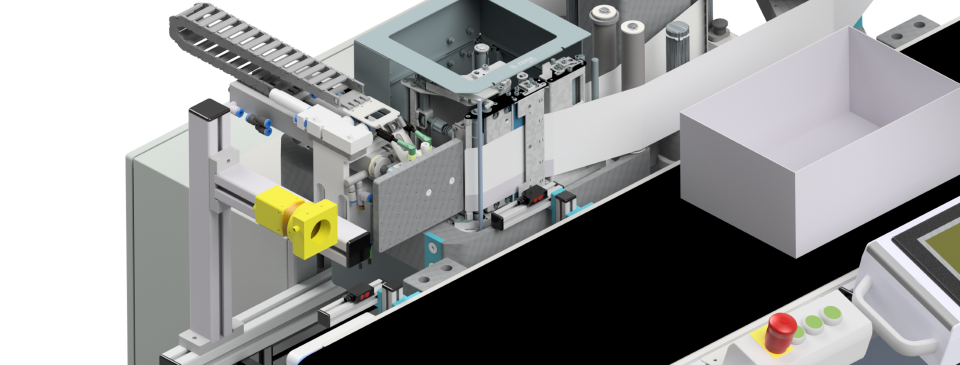

Installation-Kit for Print-Inspection Blister

For Pharma-Blisterlines and Digital Foil Printing

QualiReader Q: Product and Process Quality Inspection

QualiVision Product Quality systems for all aspects of your product, accelerate your processes and ensure quality.

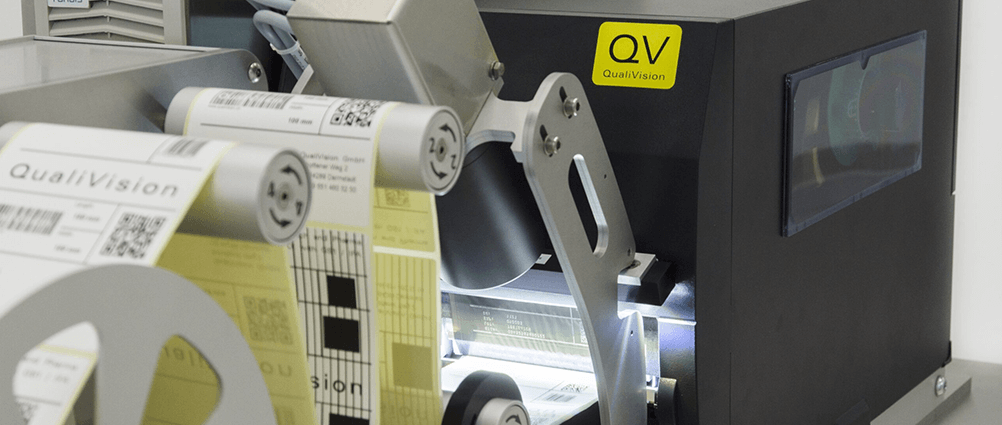

QualiVision Label Inspector

An automatic quality assurance system ensures real-time, precise label quality control to minimize risks and save space with the compact QualiVision Label Inspector.

Print and inspect for flat boxes

The ideal solution for printing and inspecting flat products, like folding boxes, that are pre-produced or packed by hand.

UELI — Universal Extendable Label Inspection

All-in-one label inspection, built for your process and setup

Installation Kit Printinspection for OEM

The Integration Kit to check your print in almost every Machinetype

Installation-Kit for Print-Inspection

For Labelling machines, Form-fill-seal machines and more

Our Industries

We cater to various industries, offering tailored solutions for pharma, medtech, food, etc. Our dedicated teams ensure customized approaches to drive success in diverse business environments.

Clinical Studies

Retail & Food